Key Benefits of AI in Manufacturing

How to approach AI in Manufacturing

57% of manufacturing companies are piloting or experimenting with AI technologies, indicating a strong trend towards AI adoption in the manufacturing sector.

What is AI in Manufacturing?

Artificial Intelligence (AI) is a form of computer science dedicated to creating systems that can perform tasks typically requiring human intelligence, such as learning, reasoning, perception, and natural language processing.

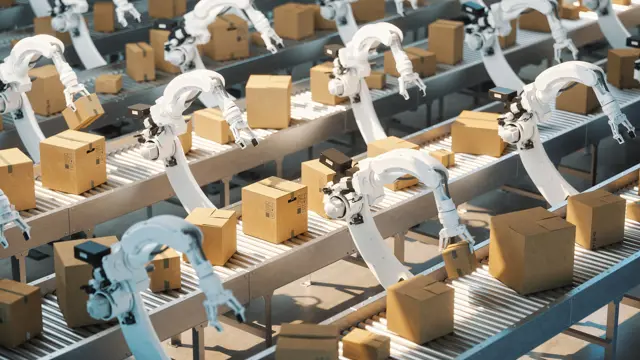

By leveraging AI, manufacturers can significantly enhance their operations. AI in manufacturing enables predictive maintenance, reducing downtime by forecasting equipment failures. It improves quality control by detecting defects with greater accuracy and speed. Additionally, it optimises production processes, minimises waste, and enhances supply chain management by predicting demand and managing logistics efficiently.

How to approach AI in Manufacturing

AI empowers manufacturers to achieve higher efficiency, productivity, and adaptability in an increasingly competitive market. However, where should organisations begin?

- Identify High-Impact Areas: Start by pinpointing areas where AI can deliver the most value quickly. This helps in justifying the initial investment and demonstrating ROI early on.

- Pilot Projects: Launch small-scale pilot projects to test AI solutions. This allows you to assess their effectiveness and make necessary adjustments without committing significant resources upfront.

- Budget Allocation: Allocate a portion of your budget to AI initiatives gradually. You can do this by setting aside money from current budgets or getting more funds from successful pilot projects.

- Phased Implementation: Roll out AI solutions in phases, starting with the most critical areas. This phased approach helps in spreading out costs over time and reduces financial strain.

- Continuous Improvement: As AI systems improve over time, reinvest savings and gains from initial implementations into further AI development.

- Employee Training: Invest in training programs to upskill your workforce. This ensures that employees can effectively use AI tools, maximising the return on your investment.

By adopting an incremental approach, you can manage costs more effectively, reduce financial risks, and build your manufacturing AI capabilities.

The first step before implementing AI

70% of companies are not leveraging their data correctly for decision-making. Getting data right is crucial for manufacturers before implementing AI for several reasons:

- Accuracy and Reliability: AI algorithms rely on large datasets to learn and make predictions. If the data is inaccurate or inconsistent, the AI’s outputs will also be flawed, leading to poor decision-making.

- Efficiency: clean, well-organised data allows AI systems to process information more efficiently, reducing the time and computational power needed to generate insights.

- Bias Reduction: ensuring data is unbiased and representative helps prevent AI systems from making skewed or unfair decisions.

- Scalability: high-quality data is essential for scaling AI applications across different processes and departments within a manufacturing organisation.

- Compliance and Security: proper data management ensures compliance with regulations and enhances data security, protecting sensitive information from breaches.

By addressing these data challenges upfront, manufacturers can maximise the benefits of AI, such as improved operational efficiency, better quality control, and enhanced innovation.

- 1

Tackling Labour Challenges

- Empowered Workforce: AI supports human workers by delivering real-time insights and intelligent recommendations, helping them make faster, more confident decisions and reducing the strain of manual analysis.

- Increased Productivity: Through AI-driven automation and smart scheduling, manufacturers can achieve more with fewer resources—addressing labour shortages and enhancing overall workforce efficiency.

- 2

Optimising the Supply Chain

- Smarter Planning and Inventory Control: Artificial Intelligence improves demand forecasting and inventory management, helping manufacturers reduce waste, avoid stockouts, and respond more effectively to market fluctuations.

- Cost-Efficient Logistics: By identifying inefficiencies and predicting disruptions, Copilot AI enhances supply chain resilience and lowers operational costs through better route planning and resource allocation.

- 3

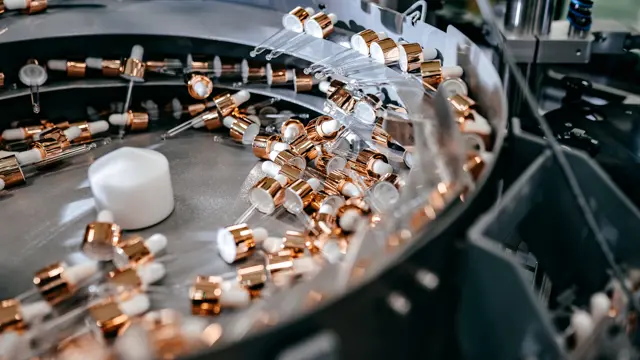

Enhancing Product Quality

- AI-Assisted Quality Control: AI detects defects early in the production process and provides actionable feedback for identifying root causes. It also supports rapid prototyping to catch design flaws before full-scale manufacturing.

- 4

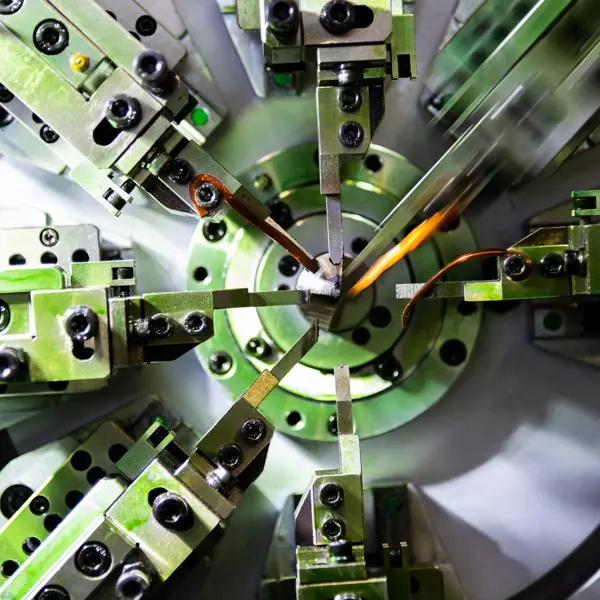

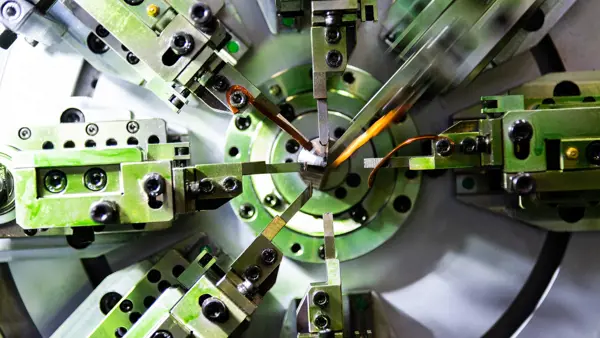

Driving Operational Efficiency

- Smart Manufacturing Processes: AI automates repetitive tasks and optimises production workflows, enabling faster throughput without compromising quality—leading to leaner, more agile operations.

- 5

Supporting Sustainability Goals

- Reduced Environmental Impact: AI helps manufacturers minimise energy consumption, material waste, and emissions by optimising resource usage and logistics, contributing to greener, more sustainable manufacturing practices.

- 6

Accelerating Innovation and Agility

- Faster Product Development and Market Response: Copilot AI enables rapid prototyping, iterative design, and real-time market analysis, helping manufacturers innovate quickly and adapt to changing customer needs or industry trends with greater speed and confidence.

Applications of Microsoft Copilot AI in Manufacturing

Case Study 1: Global Industrial Equipment Provider

Challenge: Field service teams struggled to access technical documentation and resolve equipment issues quickly, leading to extended downtime.

Solution: The company implemented Microsoft Copilot AI to assist frontline workers with real-time access to manuals, predictive maintenance data, and troubleshooting support via natural language queries.

Results:

- Faster issue resolution

- Reduced equipment downtime

- Improved collaboration between service and engineering teams

Case Study 2: Process Manufacturing Firm

Challenge: Engineering and production teams faced delays in reporting and data access, impacting decision-making and operational efficiency.

Solution: By integrating Copilot into their productivity tools, the firm streamlined reporting, improved data governance, and accelerated access to technical information.

Results:

- 35% reduction in reporting time

- 50% faster access to engineering data

- High user adoption within weeks

Case Study 3: Smart Factory Innovator

Challenge: Operators needed quicker access to telemetry data and documentation, but relied heavily on IT support, slowing down decision-making.

Solution: The company deployed Copilot within their factory intelligence platform, enabling intuitive access to KPIs, documentation, and real-time analytics.

Results:

- 50% faster data retrieval

- Reduced IT dependency

- Enhanced operational agility

Read 7 more Use Cases of AI in Manufacturing

Microsoft Copilot in Dynamics 365 Supply Chain Management and Finance is transforming the manufacturing industry by simplifying processes, reducing supply chain risk, improving financial forecasting, and increasing productivity.

Improve data quality in your manufacturing organisation

With HSO’s DnA Accelerator for Manufacturing, you will gain insights into inventory and stock-out rates. You will also learn about gross margin returns on inventory investment (GMROII) and more.

Understand how to manage your data fully, regardless of your transformation project.

Build a structured plan of your data and analytics landscape, identify the gaps, and learn how best to use your data assets.

For more information: DnA for Manufacturing

Read more

Manufacturing AI Content