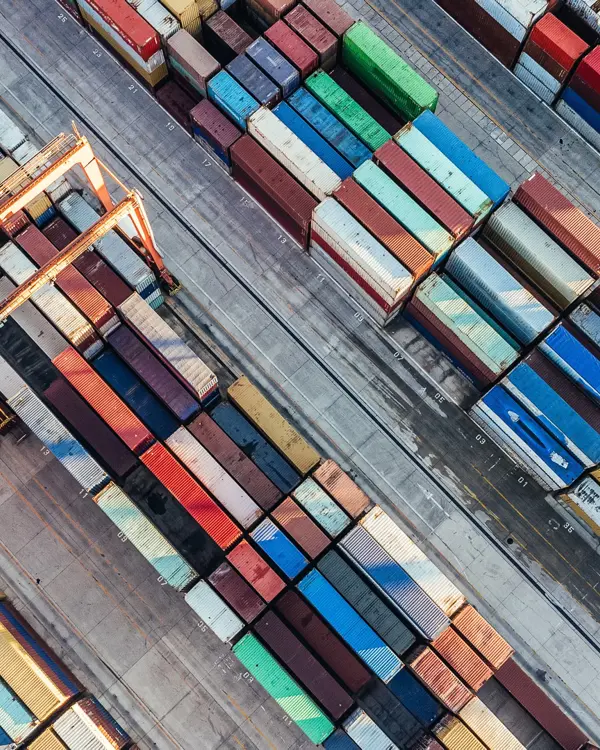

More on supply chains

How AI is transforming modern Supply Chains

In today’s volatile economy, global supply chains are under immense pressure to be faster, smarter, and more resilient. From geopolitical tensions to shifting consumer expectations, the need for agility and precision has never been greater. Yet, according to the Industrial Agility Assessment 2025, only 45% of manufacturers and distributors describe themselves as highly or extremely agile, the lowest level recorded in five years. With 64% prioritising AI adoption as part of their digital transformation strategies, artificial intelligence (AI) is emerging as a critical lever for restoring agility and competitiveness.

This blog explores how AI is revolutionising supply chain management, from predictive analytics and intelligent automation to smarter logistics, and why it’s no longer a luxury but a strategic necessity.

AI in Supply Chain

AI in supply chain management is a strategic enabler. By leveraging machine learning, predictive analytics, and intelligent automation, businesses can optimise every facet of their operations. From demand forecasting and inventory management to route optimisation and risk mitigation, AI empowers supply chain leaders to make smarter, faster decisions.

Yet despite growing interest, the Industrial Agility Assessment 2025 reveals a troubling disconnect: while 64% of manufacturers and distributors are prioritising AI adoption, only 45% feel confident in their agility, a five-year low.

As one executive put it, “You can’t just grow at all costs anymore, you need solid foundations and balance.”

This widening gap between ambition and capability underscores the need for AI not just as a tool, but as a disciplined driver of resilience, efficiency, and competitive edge.

AI for Demand Forecasting

One of the most impactful applications of AI in supply chains is demand forecasting. Traditional forecasting methods rely heavily on historical data and human intuition, often leading to inaccuracies and inefficiencies. AI revolutionises the game by analysing vast datasets in real-time, identifying patterns, and predicting future demand with remarkable accuracy.

The 2025 Industrial Agility Assessment highlights how manufacturers are increasingly utilising AI simulations to test their ability to handle various supply chain scenarios, thereby building confidence and resilience in their planning.

As one food manufacturing executive put it, “We’re looking back at performance, monitoring in real time, and simulating scenarios to test our ability to adapt. It’s building confidence and resilience.” This shift from reactive to proactive planning is helping companies maintain optimal inventory levels, reduce stockouts, and respond more effectively to market trends.

Predictive Maintenance: Minimising Downtime

AI’s predictive capabilities extend beyond forecasting into equipment maintenance, where even minor disruptions can ripple across the entire supply chain. Predictive maintenance, powered by AI, helps manufacturers avoid costly breakdowns, extend asset lifecycles, and ensure uninterrupted operations. By continuously monitoring sensor data and identifying anomalies, AI enables proactive interventions before failures occur.

In the automotive sector, for example, AI is being used to guide associates on the shop floor through spotlighting and electronic Kanban systems, tools that visually signal tasks and inventory needs in real time. This reduces complexity and human error, especially in low-volume, high-precision environments.

As one automotive executive shared in the Industrial Agility Assessment 2025, “We’re using AI to simplify complexity. It’s not just about automation; it’s about guiding people with the right information at the right time.” This blend of human-machine collaboration is helping manufacturers maintain uptime, improve quality, and respond faster to operational risks.

Route Optimisation

Transportation is one of the most complex and cost-intensive components of supply chain operations. AI-powered route optimisation tools are transforming logistics by analysing traffic patterns, fuel efficiency, weather conditions, driver behaviour, and safety standards to determine the most efficient delivery routes. This not only provides cost savings on transportation but also improves delivery speed and sustainability, critical factors in today’s competitive landscape.

But AI’s impact goes beyond routing. According to the Industrial Agility Assessment 2025, manufacturers and distributors are increasingly using digital tools to streamline administrative workflows tied to logistics. By automating manual steps such as delivery scheduling, invoicing, and compliance checks, companies are freeing up staff to focus on higher-value tasks like customer engagement and business development.

As one executive noted, “We’ve removed layers of admin and complexity. Now our teams can focus on what really matters, serving customers and growing the business.” This shift toward intelligent logistics is helping organisations reduce operational friction, improve responsiveness, and build more agile supply chains.

Machine Learning in Logistics

Machine learning (ML) in logistics is rapidly evolving from a back-end analytical tool to a frontline enabler of supply chain resilience. Beyond optimisation, ML algorithms continuously learn from operational data to detect anomalies, such as unexpected delays, demand spikes, or supplier inconsistencies, and trigger early warnings before disruptions escalate. These systems can flag deviations from normal patterns, recommend corrective actions, and even simulate alternative scenarios to guide decision-making.

However, the Industrial Agility Assessment 2025 reveals that many organisations are still struggling to unlock the full potential of Machine Learning.

57% of manufacturers cite data readiness, 56% point to skills gaps, and 55% highlight system integration challenges as major barriers to AI and ML deployment. These figures underscore the importance of foundational digital maturity; without clean, connected, and accessible data, even the most advanced algorithms will fall short.

As one engineering leader put it, "We’re keeping abreast of developments, but we don’t see a clear use case yet. For us, data optimisation gives a more tangible benefit than AI.” This reflects a common view in the industry: machine learning (ML) is powerful, but it only works well when it supports business goals, has strong data systems behind it, and the team knows how to use it.

For manufacturers and distributors who are ready, ML can help reduce risks and make smarter, faster decisions throughout the supply chain.

Lessons from the Pandemic Era

While the COVID-19 pandemic may now be behind us, its impact on supply chain thinking remains profound. The crisis exposed vulnerabilities in global logistics, supplier dependencies, and inventory strategies. It also accelerated digital transformation, with AI emerging as a key tool for navigating uncertainty. Many of the AI-driven innovations discussed in this blog were fast-tracked during the pandemic and are now foundational to modern supply chain resilience.

The AI Frontier

Despite the promise, AI adoption is tempered by realism. Many SMEs remain cautious, citing unclear use cases and limited resources. As one engineering leader noted: “For us, data optimisation gives a more tangible benefit than AI. We’re keeping abreast of developments, but we don’t see a clear use case yet.”

Even those adopting AI stress the importance of problem-first thinking. “The key is identifying the problem AI can solve, not starting with the tool and working backwards,” said an automotive manufacturer.

Outlook: Efficiency, Agility, and Measured Innovation

Looking ahead, the top priorities for the next 12–24 months, according to the Industrial Agility Assessment 2025, are improving agility (60%), introducing AI to enhance decision-making (52%), and reducing time and cost to launch new products (46%). The emphasis is on efficiency and resilience rather than bold transformation.

As one food manufacturing executive said: “We’ve shifted our strategy from pure growth to profitable growth. You can’t just grow at all costs anymore, you need solid foundations and balance.”

Conclusion: How AI Is Transforming Modern Supply Chains

AI is no longer a futuristic concept; it’s a present-day catalyst for supply chain transformation. From forecasting and automation to smarter decision-making, AI empowers organisations to navigate complexity, enhance resilience, and drive growth.

The 2025 Industrial Agility Assessment paints a picture of a sector consolidating its gains, embedding lessons from the past five years, and focusing on strengthening foundations. Manufacturers and distributors are choosing balance over boldness, foundations over disruption.

Agility, then, is no longer about constant reinvention. It’s about building resilience, efficiency, and flexibility to adapt without exhausting people or resources. Those organisations that can embed this discipline will be best placed to weather ongoing uncertainty and to seize opportunities when conditions allow.

Ready to explore how AI can elevate your supply chain strategy?

Discover where your organisation stands on the path to intelligent transformation with the Industrial Agility Assessment, a comprehensive evaluation conducted by The Manufacturer and sponsored by HSO. This free resource helps manufacturers and distributors pinpoint their current capabilities, uncover areas for improvement, and build a strategic roadmap towards AI-driven supply chain excellence.

Download the Assessment now to start shaping a smarter, more agile future.