Read more

Featured customer success stories

Sparck Technologies live within 6 months with Dynamics 365 ERP

Through a unique approach, clear conditions and a dose of ‘Friese’ common sense, Sparck Technologies and HSO realized a fully operational ERP system based on Dynamics 365 well before the set deadline.

A Dynamics 365 ERP implementation in 6 months? HSO accepts the challenge

Realize an ERP implementation at a high-tech manufacturing company within 6 months? Impossible, was HSO's first reaction when we received this unusual request. The opposite turned out to be true. Through a unique approach, clear conditions and a dose of ‘Friese’ common sense, Sparck Technologies and HSO realized a fully operational ERP system based on Dynamics 365 well before the set deadline.

Kees Oosting, CEO at Sparck Technologies and HSO colleagues Otto Buurman, Enterprise Solution Architect and Erik Joosen, Lead SCM Consultant look back on this special project.

Sparck was part of the French stocklisted company Quadient for decades, but in 2021, the packaging activities within Quadient were sold, making Sparck an independent SME again. Kees: ‘As a result of the carve out, the business had to pick up the use of new IT systems, including CRM and ERP. For CRM we were using Salesforce and for the production environment SAP. We obviously examined different applications. Do we want to continue with SAP, do we choose Infor or Microsoft Dynamics?

SAP was dismissed because the consultants constantly kept the door open for customization, adjustments and special requests. But that's exactly what we didn't want. Our team quickly became enthusiastic about Dynamics 365, so then it came down to choosing the right partner.

In every case, we wanted an implementation partner with international experience and allure and who actually has an international presence. That's where HSO came in very well. But in the end, it was the people at HSO who made the difference for us. The consultants showed that they understand our processes and know how a manufacturing company works, how logistics works."

A high-tech start-up with a rich history

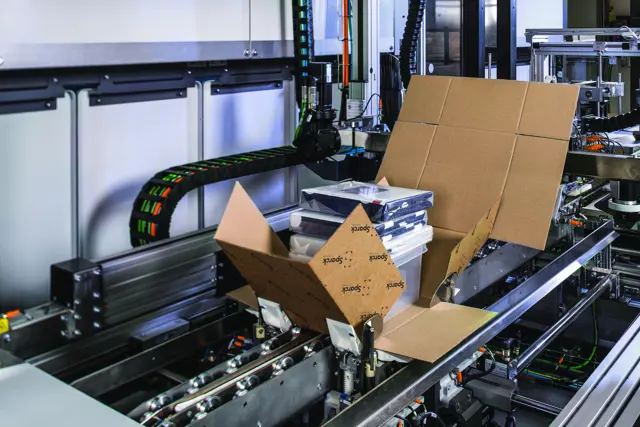

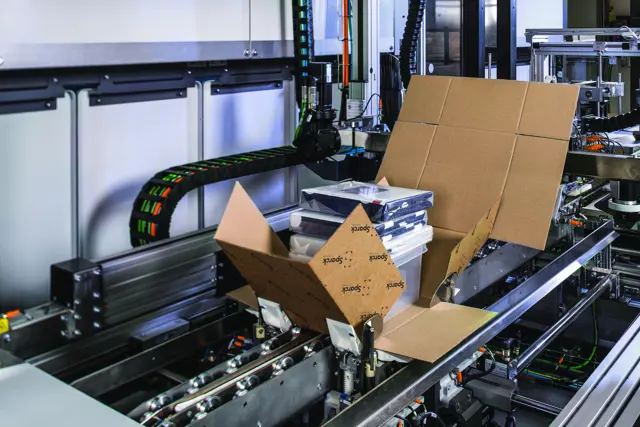

Founded in 1924 in Drachten, Sparck Technologies created and fabricated the world’s first clog production machine. Almost a century later, Sparck is still focused on automation innovations that help businesses streamline operations. With the rise of ecommerce Sparck started to design and fabricate fit-to-size automated packaging systems for online retailers.

Using 3D scanning technology, these fit to size automated packaging solutions build, seal and label a perfectly sized shipping box around each unique order in just a matter of seconds. Sparck’s packaging systems have the capacity to tailor-make up to 1,100 packages per hour.

A shared vision and approach

Kees continues: "HSO understood very well what we needed, but initially thought they would not be able to realize the project within the very limited time. I was convinced that it could be done, but only with a very clear vision and under very specific conditions.

For example, we didn't want to spend a single euro on customization. The implementation is 100% standard functionality, and in that respect Dynamics 365 is already an very rich solution. A second important factor was the team. I ensured 100% availability of four key users and gave them the responsibility to make this project a success.

Long story short: after we made clear agreements about the scope, we went to work. In the end, even more was implemented than we had set in advance. We met our time goal generously, without people having to work weekends, and we stayed well within our budget."

Kees: "An important success factor for this project was definitely the commitment on our part and from HSO. We put together a very good team that can work together under the motto 'a deal is a deal'.

In addition, keep it simple and focus on the primary process are crucial. This is why we asked HSO to be prescriptive. Here I like to make the analogy with cars. When I buy a new car, you don’t need to explain the purpose of the car, but all you have to do is explain to me how it works and what the controls are for. The primary function of the car has not changed. Similarly, the core of any ERP system still contains the processes of my very first implementation ever. Our SAP car was in the basics very good, but 20 years old. Now we have a fancy new car - and you certainly have to embrace the new capabilities - but most of all you need to have a partner who is very good at explaining how it works.”

'Say what you do and do what you say'

Kees is very pleased with HSO. "The commitment and the fact that HSO took on the challenge of this 'impossible task' is typical of the company. In that respect, HSO fits well with Sparck's culture: a deal is a deal and say what you do and do what you say."

Read more

Featured customer success stories

The HSO team looks back

The HSO project team included Otto Buurman, Enterprise Solution Architect and Erik Joosen as Lead SCM (Supply Chain Management) Consultant. Both look back on the project with a certain pride.

Otto: "Normally we take at least a year to eighteen months for an ERP implementation at a manufacturing company. Implementing a manufacturing company in six months therefore seemed an impossible task. We had to think about that carefully."

Otto explains the method: "For the project to be successful, we needed absolute focus. Therefore, especially in the first period, we worked with the team exclusively from our team room in Veenendaal. We worked with three-week sprints and in the fourth week the team from Sparck came to us to test and to prepare the next sprint."

Erik adds: "To make communication as efficient as possible, the team agreed that only two consultants, one for Operations and one for Finance, would be the point of contact for Sparck's team and for managing the HSO team. That took some getting used to, but it ultimately reduced distractions and white noise. It allowed us to make decisions and move forward swiftly."

"We were asked to be absolutely prescriptive. Based on the standard, we determined what the minimum system should look like."

Strong focus and excellent collaboration

Otto: "After the setup, data migration threatened to become a bottleneck. The Sparck team was responsible for data migration, testing and training. We then prioritized data migration and that turned out to be the right choice. In the end, Sparck went live very smoothly. The after-care we had stand-by turned out to be hardly necessary."

Erik: "Clear preconditions and agreements have certainly contributed to the success of the project. These created clear focus and excellent collaboration within the team. And, of course, Kees' vision: nothing but the standard and no room for any customization whatsoever. The time pressure also helped in a way, because everyone wanted to make this a success. Initially, it seemed an impossible request, but after thorough discussions, this tilted and it became a challenge instead."

Otto: "Currently, ERP is operational, it’s running well and in the meantime we are preparing for Field Service, which we also want to implement based on our best practices and standard Dynamics 365 Service software."

"This project shows that a standard implementation based on best practices can work very well. After all from our experience we know how things work in a production company and how the software can best support the processes."

Watch the video

Kees Oosting, CEO of Sparck Technologies: "HSO is a partner that can follow us into the future"

Due to your cookie preferences, we cannot show you this content. Accept the cookies to be able to view this content.

Read more

On Carve-Outs, Cloud Strategy and Architecture

HSO is responsible for Sparck's complete digital transition. In addition to the carve-out of workstations, Outlook, Teams and SharePoint, CRM and ERP followed. The next step is the implementation of Field Service, including (data) integrations. Would you like to learn more about our carve-out expertise or manufacturing best practices? Please contact us.

We, and third parties, use cookies on our website. We use cookies to keep statistics, to save your preferences, but also for marketing purposes (for example, tailoring advertisements). By clicking on 'Settings' you can read more about our cookies and adjust your preferences. By clicking 'Accept all', you agree to the use of all cookies as described in our privacy and cookie policy.

Purpose

This cookie is used to store your preferences regarding cookies. The history is stored in your local storage.

Cookies

Location of Processing

European Union

Technologies Used

Cookies

Expiration date

1 year

Why required?

Required web technologies and cookies make our website technically accessible to and usable for you. This applies to essential base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

Purpose

These cookies are stored to keep you logged into the website.

Cookies

Location of Processing

European Union

Technologies Used

Cookies

Expiration date

1 year

Why required?

Required web technologies and cookies make our website technically accessible to and usable for you. This applies to essential base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

Purpose

This cookie is used to submit forms to us in a safe way.

Cookies

Location of Processing

European Union

Technologies Used

Cookies

Expiration date

1 year

Why required?

Required web technologies and cookies make our website technically accessible to and usable for you. This applies to essential base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

Purpose

This service provided by Google is used to load specific tags (or trackers) based on your preferences and location.

Why required?

This web technology enables us to insert tags based on your preferences. It is required but adheres to your settings and will not load any tags if you do not consent to them.

Purpose

This cookie is used to store your preferences regarding language.

Cookies

Why required?

We use your browser language to determine which language to show on our website. When you change the default language, this cookie makes sure your language preference is persistent.

Purpose

This service is used to track anonymized analytics on the HSO.com application. We find it very important that your privacy is protected. Therefore, all data is collected and stored on servers owned by HSO with no third-party dependencies. This cookie helps us collect data from HSO.com so that we can improve the website. Examples of this are: it allows us to track engagement by page, measuring various events like scroll-depth, time on page and clicks.

Cookie

Purpose

This cookie enables HSO to run A/B tests across the HSO.com application. A/B testing (also called split testing) is comparing two versions of a web page to learn how we can improve your experience. All data is collected and stored on servers owned by HSO with no third-party dependencies.

Purpose

With your consent, this website will load Google Analytics to track behavior across the site.

Cookies

Purpose

With your consent, this website will load the Microsoft Clarity script, which helps us understand how people use the site. The cookies set by Clarity collect session-level data like how the visitor landed on the site, which pages they viewed, their language preference, and even their general location. This data powers Clarity’s features like heatmaps and session recordings, helping us see which parts of a page get attention and where users drop off. The goal isn’t to track individuals, but to understand patterns that can improve the user experience. Learn more about Microsoft Clarity cookies here.

Cookies

Technologies Used

Cookies

Purpose

With your consent, this website will load the Google Advertising tag which enables HSO to report user activity from HSO.com to Google. This enables HSO to track conversions and create remarketing lists based on user activity on HSO.com.

Possible cookies

Please refer to the below page for an updated view of all possible cookies that the Google Ads tag may set.

Cookie information for Google's ad products (safety.google)

Technologies Used

Cookies

Purpose

With your consent, we use IPGeoLocation to retrieve a country code based on your IP address. We use this service to be able to trigger the right web technologies for the right people.

Purpose

With your consent, we use Leadfeeder to identify companies by their IP-addresses. Leadfeeder automatically filters out all users visiting from residential IP addresses and ISPs. All visit data is aggregated on the company level.

Cookies

Purpose

With your consent, this website will load the LinkedIn Insights tag which enables us to see analytical data on website performance, allows us to build audiences, and use retargeting as an advertising technique. Learn more about LinkedIn cookies here.

Cookies

Purpose

With your consent, this website will load the Microsoft Advertising Universal Event Tracking tag which enables HSO to report user activity from HSO.com to Microsoft Advertising. HSO can then create conversion goals to specify which subset of user actions on the website qualify to be counted as conversions. Similarly, HSO can create remarketing lists based on user activity on HSO.com and Microsoft Advertising matches the list definitions with UET logged user activity to put users into those lists.

Cookies

Technologies Used

Cookies

Purpose

With your consent, this website will load the Microsoft Dynamics 365 Marketing tag which enables HSO to score leads based on your level of interaction with the website. The cookie contains no personal information, but does uniquely identify a specific browser on a specific machine. Learn more about Microsoft Dynamics 365 Marketing cookies here.

Cookies

Technologies Used

Cookies

Purpose

With your consent, we use Spotler to measures more extensive recurring website visits based on IP address and draw up a profile of a visitor.

Cookies

Purpose

With your consent, this website will show videos embedded from Vimeo.

Technologies Used

Cookies

Purpose

With your consent, this website will show videos embedded from Youtube.

Cookies

Technologies Used

Cookies

Purpose

With your consent, this website will load the Meta-pixel tag which enables us to see analytical data on website performance, allows us to build audiences, and use retargeting as an advertising technique through platforms owned by Meta, like Facebook and Instagram. Learn more about Facebook cookies here. You can adjust how ads work for you on Facebook here.

Cookies

Purpose

With your consent, we use LeadInfo to identify companies by their IP-addresses. LeadInfo automatically filters out all users visiting from residential IP addresses and ISPs. These cookies are not shared with third parties under any circumstances.

Cookies

Purpose

With your consent, we use TechTarget to identify companies by their IP address(es).

Cookies

Purpose

This enables HSO to personalize pages across the HSO.com application. Personalization helps us to tailor the website to your specific needs, aiming to improve your experience on HSO.com. All data is collected and stored on servers owned by HSO with no third-party dependencies.

Purpose

With your consent, we use ZoomInfo to identify companies by their IP addresses. The data collected helps us understand which companies are visiting our website, enabling us to target sales and marketing efforts more effectively.

Cookies