Common Challenges in Manufacturing

Unifying Systems for Manufacturing Success and Rapid ROI

In today's fast-paced manufacturing environment, companies face numerous challenges, particularly when it comes to managing multiple legacy ERP systems. These challenges often arise from growth through acquisitions, leading to a complex web of disparate systems that hinder operational efficiency and decision-making. However, innovative solutions are available to help manufacturers streamline their operations and achieve rapid ROI.

HSO and Aptitude Software: A Powerful Partnership

HSO, a global Microsoft solution integrator, and Aptitude Software, a leader in finance and technology solutions, have joined forces to address these challenges. By leveraging their combined expertise, they offer manufacturers a comprehensive approach to unifying systems and optimizing financial processes.

- 1

Multiple legacy ERP systems due to acquisitions

Acquisitions often introduce a range of disparate ERP systems that were independently implemented by the acquired companies. This creates a fragmented IT infrastructure, making it difficult for manufacturers to integrate operations and achieve a cohesive system. The disparities between these systems can lead to inefficiencies, increased costs, and challenges in maintaining consistent workflows across the organization.

- 2

Inconsistent financial data across different systems

When multiple ERP systems are in use, financial data is often stored in various formats, leading to discrepancies and a lack of uniformity. This inconsistency makes it challenging to consolidate financial data for reporting or auditing purposes, potentially resulting in errors or delays in financial decision-making. Uniformity in financial data is critical to ensuring accurate and timely insights.

- 3

Difficulty in achieving real-time data access for informed decision-making

Fragmented systems often impede the ability to access up-to-date data promptly. This lack of real-time visibility into operations can hinder decision-makers from responding quickly to market changes or operational challenges. By the time data is consolidated and analyzed, opportunities may already have been lost or threats may have escalated, impacting organizational agility.

- 4

Slow and difficult onboarding for acquisitions

When a new company is acquired, integrating its operational and financial systems into the existing infrastructure can be a lengthy and resource-intensive process. The lack of standardization across ERP platforms adds to the complexity, resulting in delays that can obstruct the speed at which a newly acquired entity starts contributing value to the parent organization.

Innovative Solutions for Incremental Transformation

HSO and Aptitude Software propose an incremental and agile approach to ERP and finance transformations in Manufacturing. This involves:

- Consolidating financial data from multiple ERP systems.

- Implementing a centralized accounting policy to ensure consistency.

- Utilizing Aptitude's Finance Platform to manage granular financial data and automate manual tasks.

Key Use Cases

There are many different use cases but we’ve highlighted two that will resonate with manufacturing companies that have undergone acquisition activity or have rolled out best-of-breed systems over time. These two primary use cases illustrate the benefits of delivering incremental and agile finance transformation approaches.

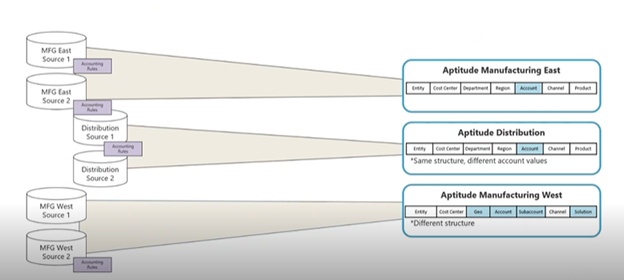

1.Multi-GL and Multi-Chart of Accounts (COAs) Situations:

Multiple GLs and Chart of Accounts are complex to manage, with duplication, reduced control, and manual overhead. Aptitude's Finance Platform can handle journals from various source systems, regardless of their format, and map them to a unified chart of accounts. This ensures accurate consolidation and reporting.

2.Centralized Accounting

Accounting rules managed across multiple systems cause a lack of consistency, financial control, and manual overhead. By centralizing accounting rules and policies, manufacturers can reduce reliance on IT for accounting changes, minimize risks, and improve processing times.

Manufacturers and AI Usage

21%

of Manufacturing respondents indicated that AI is extensively integrated in finance.

45%

indicated concerns around data privacy and security related to AI usage, this is higher compared to the global average of 35%.

3

of the top benefits of AI investment for manufacturers are efficiency, advanced data insights and better accuracy.

21%

of manufacturers placed themselves at the traditional stage of the autonomous finance journey (defined by siloed source systems and heavy use of end user computing tools) – the lowest by any sector.

Driving Competitive Advantage

For manufacturers, achieving a unified system and leveraging real-time data can significantly enhance their competitive edge. By adopting innovative finance solutions and automating manual processes, they can:

- Improve operational efficiency.

- Make more informed business decisions.

- Accelerate growth and achieve rapid ROI.

The collaboration between HSO and Aptitude Software offers manufacturers a powerful solution to unify their systems and optimize financial processes. By addressing common challenges and leveraging cutting-edge technology, manufacturers can achieve greater efficiency, better decision-making, and a stronger competitive position in the market.

Autonomous Finance Assessment

We’d like to invite you to take an assessment that will help you assess, benchmark and accelerate your journey towards autonomous finance in just a few minutes. Fill out the form below to access the tool.