Product Development

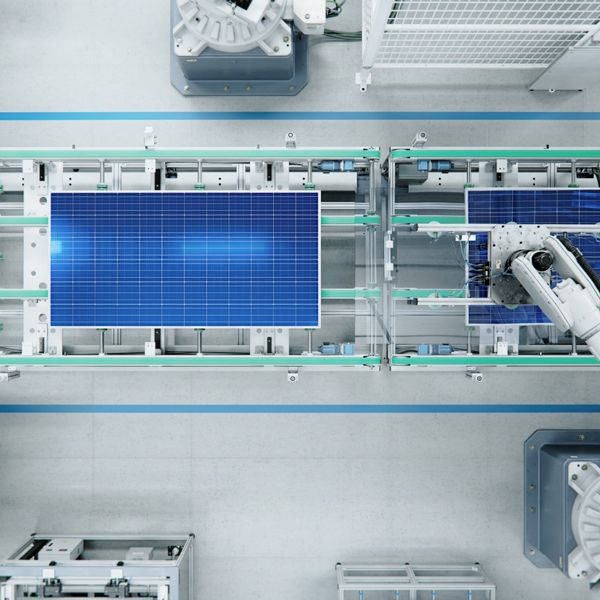

Manufacturing Agility: Product Development

“Logic will get you from A to B. Imagination will take you everywhere.” – Albert Einstein. Imagination is the only limitation to developing new products. It’s this, combined with the right tools and support of a connected supply chain, that makes adapting to change possible, and profitable.

Technology has helped some businesses shift their entire operating model to better predict and adapt to change. Take retail, for instance. An industry hard hit in recent times. 11,000 retail outlets shut in the first half of 2020, twice as many as in same period the previous year. This has forced many businesses to evolve and create more agile routes to get from imagination, to manufacturing, to launch.

Adapting to, and profiting from change

Change can bring uncertainty but also opportunity if you take an agile approach. For example, you’re a business focused on selling product in stores. But the climate shifts. Customers are buying more online. Traditional bricks and mortar retailing is now unprofitable. You close your stores and develop an online and franchised model. Focus is now on pushing products through partner stores and improving your online experience.

You now need to support a complex three-way agreement between your business, your manufacturing partners, and the franchisee. Existing systems are not scalable enough to support this. Neither can you afford the cost of hiring more staff to manage the process. You need a connected platform approach built on a common data service.

Data that flows up stream and down. Moving between centralised Product Lifecycle Management (PLM), Product Information Management (PIM), Finance & Operations, and other systems in the supply chain.

Data moving through the centralised PLM increases visibility. There is now greater detail of product development, and more accessibility. Now you, your manufacturing partners, and designers can collaborate. Each adding their own input into the creation of new products; colour, size, style, line the products fall into, and all the things needed to create a product before it’s released for manufacturing and sale. Product development is now a collaborative effort.

Data moving through the centralised PIM provides supporting product images, text and detail that franchise partners then use. With access to the same data, everyone in the supply chain is now seeing the same version of the truth. As a result, removing bottlenecks and getting products to market is faster and less costly for everyone involved. Technology has enabled products to move quickly between imagination and development, fast.

One system to guide them all

Systems disparate from one another create bottlenecks. They require manual processes to ensure information flows between them, which is costly.

Making information available, clear and upfront within a connected platform allows all parties to plan better; essential when order conditions dictate manufacturing cost.

When it comes to cost, increasing visibility helps increase understanding of order requirements. Those requirements drive costs of manufacturing, so if you can increase orders to go above a break point, the cost is reduced for everybody.

This only comes with a single connected platform, which simplifies even complex three-way agreements, by increasing visibility. Visibility which comes by having data available to everyone. Manufacturers can now plan requirements in advance and gain more control of cost.

From imagination to the customer

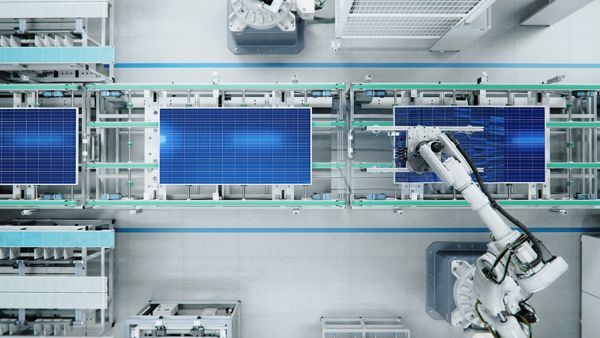

Platforms such as Microsoft Dynamics 365 connect the systems and processes involved in product development. Process flows move data between systems making it accessible to everyone. From CAD design and prototyping, through to master planning, sales order creation and beyond, everyone in the supply chain operates from a single view of the truth.

Operating portals provide upfront visibility of what products are coming. Manufacturers can now advance plan, with a view of product stages and their critical path. Portals also provide order visibility such as item cost, the look of the finished product, delivery times, and all the things the customer needs. Tools such as Microsoft Azure Synapse, Analytics and Power BI then provide extra visibility and reporting.

A connected platform gives manufacturers the agility needed to adapt product development alongside change, increasing collaboration and bringing imagination to life.

Agility and speed offer a competitive advantage for today’s manufacturer. To discover how HSO can help you reduce your time to market, book your complimentary, no obligation consultation to understand what Microsoft Dynamics 365 can do for your organisation.