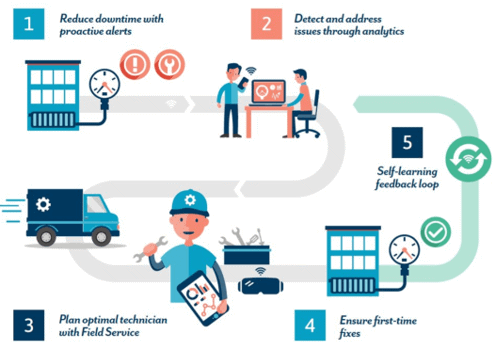

Five steps to smart maintenance

Step 1. Data collection and the IoT

Step one in the smart maintenance chain is data collection. Thanks to the Internet of Things (IoT), devices, machines and products are connected to each other. And, with the help of sensors, information is collected 24/7 about consumption, temperature, vibration, pressure, capacity and humidity, among other things. You can also source data from external sources that affect the quality and life of your product. Think about weather forecasts.

In addition to IoT data and external data, you probably also have relevant information at your disposal from your ERP or CRM environment, such as product and customer information, that you want to include in your analyses.

Step 2. Analyzing data, modeling and identifying issues

The second step in the chain is to analyze the data and create models so that you can then identify certain deviations – or issues. Depending on the number of data sources and the quality of the data, it is cleansed and, if necessary, edited.

Step 3. The right action at the right time

Next is the step from data insight to actually improving and influencing the business process. For example, scheduling the right mechanic via Dynamics 365 Field Service, but other call-to-actions are also possible. If the measured or calculated information reaches certain values, an alert is generated after which a workflow starts. Subsequently, a mechanic or other action can be scheduled fully automatically.

Step 4. The result? Your assets are optimally monitored

With smart maintenance you can ensure that you stay ahead of failures and optimize the process. You extend the lifespan of machines by carrying out timely maintenance and you only go to a machine or piece of equipment if you have a good data-driven reason to do so. With smart maintenance you can prevent downtime and increase efficiency.

Step 5. Self-learning feedback loop

Continuous improvement is the key to the success of smart maintenance. By continuing to learn, the entire chain becomes smarter and smarter. More and more information about your machines and usage is becoming available, allowing you to make more and more accurate predictions. In fact, the model looks at the predictions that are correct and those that are incorrect and then the model starts to train itself (self-learning) to learn from mistakes.